Industry

Virtual Reality Technology in the Manufacturing Industry

The use of VR in the manufacturing industry is a perfect example of how businesses in a well-established non-digital field can take advantage of Mazer.

Presenting the intricacies of the manufacturing process in virtual reality will give your customers a better understanding of the products and services you have to offer them.

Mazer’s proprietary functionality allows your business to create a multi-space VR showroom which is fully integrated with your existing website. This will enable you, among other things, to demonstrate your manufacturing process and show off your goods catalogue, or it can simply act as a luxurious high-tech meeting space.

Mazer’s engineered metaverse spaces can be applied to sales presentations at manufacturing industry trade shows where potential customers can meet your specialized sales staff or other company representatives. With VR technology, these individuals don’t even have to be located at the show; they can take customers on a tour of your facility from the other side of the globe.

How you can use XR in manufacturing industry?

Find below examples of use cases for Process & Production Line Supervisors.

Oversee critical manufacturing processes and keen on elevating the efficiency of onboarding and training?

How to use XR solutions in manufacturing industry?:

- Seamless Onboarding: Virtually train new employees without halting or slowing down the production lines, ensuring uninterrupted output.

- Safety First: Simulate potentially hazardous situations within a controlled, virtual environment, allowing employees to practice without real-world risks.

- Repetitive Learning: Offer the ability to revisit and practice specific scenarios multiple times, ensuring complete understanding and proficiency before engaging in real-world tasks.

Step into a new era of production with Mazer – where efficiency meets safety, ensuring your team is prepared for every challenge on the production floor.

Mazer’s virtual reality improves the manufacturing process

The digital twin is the most well-known application of VR in manufacturing. The manufacturing process can be improved by the creation of a virtual reality representation of a factory or a particular piece of equipment. Integrating the VR representation with its real-world counterpart and supplying it with real-time manufacturing data creates a virtual reconstruction of the process which can be used to simulate different production scenarios, thus powerfully assisting in the decision-making process.

Mazer’s unique feature allows virtual reality objects to be handled simultaneously by several different workers. Despite being located all over the globe, engineers can work on the virtual manufacturing line at the same time and analyze the digital twin together.

Remote technical assistance

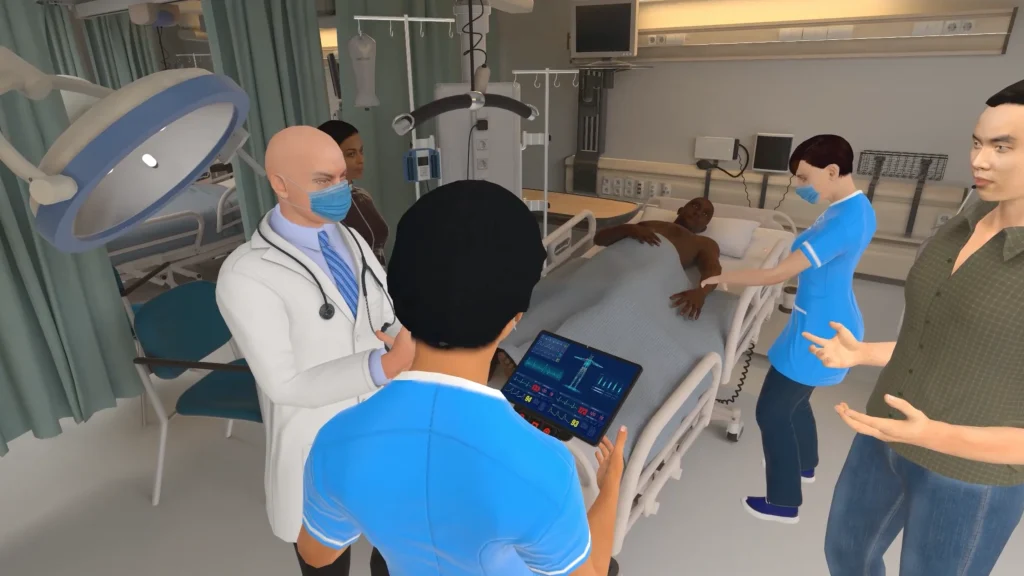

When your on-site employees face a technical issue they cannot overcome, they can take advantage of Mazer’s ability to create a virtual reconstruction of a real space.

Employees can simply put on their augmented reality glasses while the troubleshooting expert uses either a computer or virtual reality headset to direct them. Throughout this virtual meeting, the expert’s suggestions and annotations will be projected from his or her device onto the augmented reality glasses worn by the employees.

This seemingly futuristic process is already being used in various industries and is the modern way to efficiently diagnose and address complex technical issues.

Unlock the future with Mazer: Your innovation partner.